Product description:

The digital wireless grain condition measurement and control system is a system that uses computer and electronic technology to detect, store and analyze grain conditions, and to control grain storage technology facilities in a timely manner. It mainly includes two parts: grain condition measurement and control hardware and measurement and control software. The system has basic functions such as grain condition detection, grain condition analysis, grain condition data storage and printing temperature and humidity. It can also expand related functions of new grain storage technologies such as intelligent ventilation and nitrogen air conditioning to meet the requirements of grain storage business management information system and grain condition. Monitoring system requirements.

System Features:

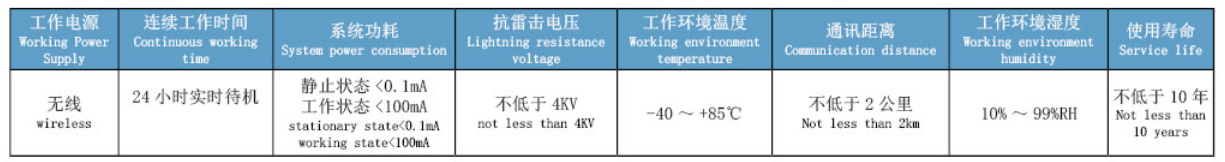

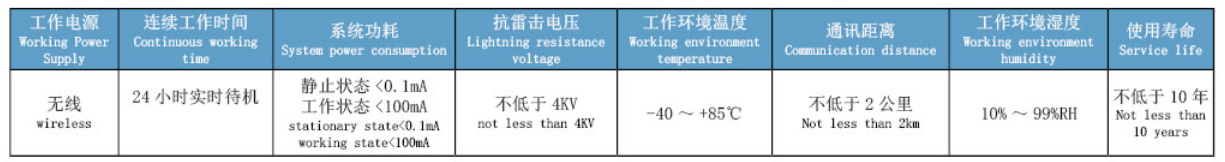

1. The system uses 433HZ (GSM) frequency band, working voltage: DC 3-5.5v2, direct sequence spread spectrum (DSSs), and has strong anti-interference ability.

3. Adopt ZigBee technology and comply with IEEE802.15.4 standard.

4. The extension uses a dual-core CPU to fully ensure data exchange in the processing center. The detection speed is fast and the system backup is complete, which effectively ensures the normal operation of the extension and greatly reduces the failure rate of the extension.

5. Functions of JLLQ-1.0 system

6. Various indicators of system functions of JLLQ-1.0.

Main performance indicators:

The temperature sensor uses the American DALLS high-precision digital chip 18B20. Measuring range -40~85℃.

The humidity sensor uses the French original HM1550 humidity sensor with a measurement range of 0~99%RH.

High precision: temperature measurement error ≤ ±0.1℃; humidity measurement error ≤ ±2%RH;

High stability: temperature repeatability error ≤ ±0.1℃; humidity repeatability error ≤ ±0.5%RH;

Large capacity: The measuring point capacity of a single extension can reach 1024 points;

Rapid detection: detection speed is not less than 100 points/second;

Wireless communication: Communication can be achieved within the reach of the public Internet or mobile phone text messages.

System Components:

Data management:

Data storage: Automatically save and back up the data of each detection. In order to facilitate data management and analysis, the database real-time detection data and scheduled detection data are stored in the corresponding database. Perform functions such as calculation, statistics, summary, save, import, export, recovery, and deletion of all data. Data retrieval: Users can query real-time and scheduled inspection data of any warehouse on any date as needed.

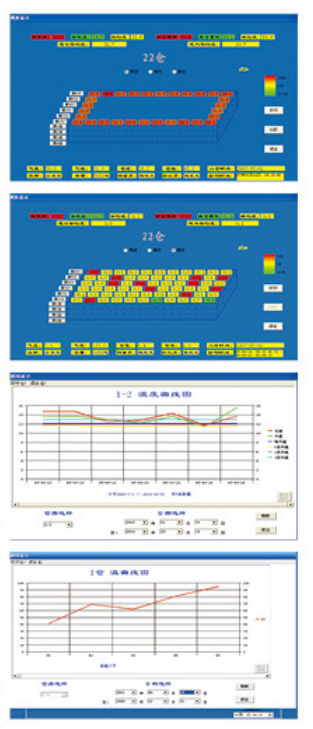

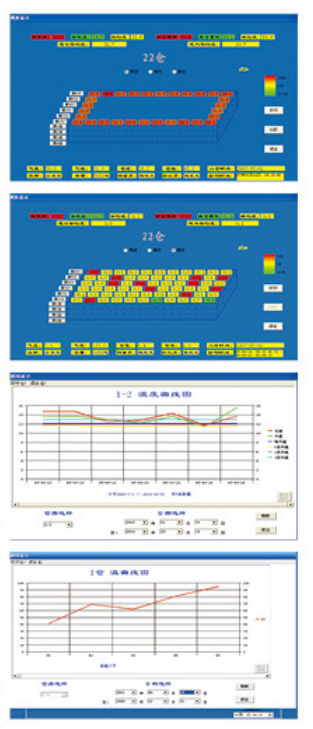

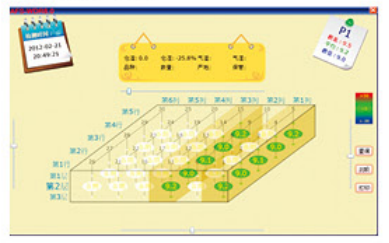

Data display: Display the grain temperature values of various parts of the warehouse in various forms.

Three-dimensional graphic display: display the temperature value with continuously changing color barcodes. Attached are the graphics (square warehouse, shallow round warehouse).

Three-dimensional digital display: displays the temperature value with numbers and continuously changing colors.

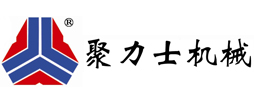

Curve display: display the single curve and compound curve (curve graph) of each temperature point and humidity point in time (year, quarter, month, day, etc.). Table display: Display data in a universal, easy-to-understand table.